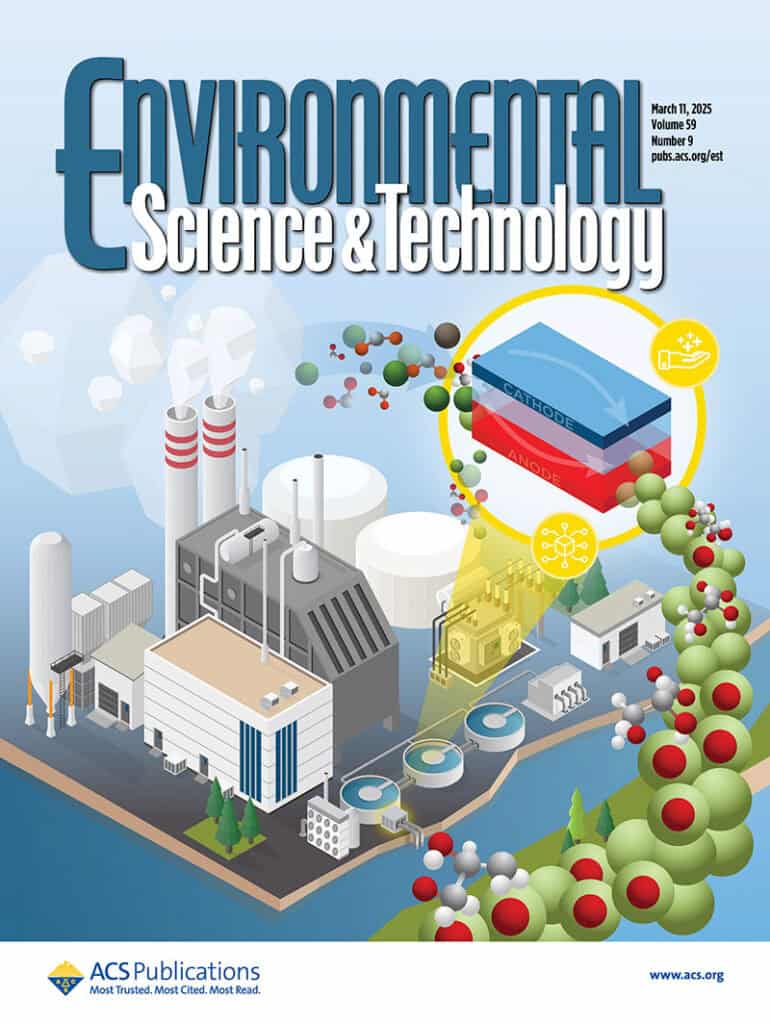

Biodiesel wastewater treatment: Capturing carbon and valuable chemicals

A new experimental design tests catalyst stability in an electrochemical method for treating environmental waste streams while capturing valuable co-products

A new experimental design tests catalyst stability in an electrochemical method for treating environmental waste streams while capturing valuable co-products

While biodiesel provides a cleaner-burning alternative to petroleum diesel, it produces CO2 and hazardous wastewater during manufacturing, requiring extra steps to achieve sustainability. A diagnostic study led by University of Michigan researchers works to improve a process that captures CO2 while treating biodiesel wastewater and produces valuable co-products like fuels and green chemicals.

During biodiesel production, fats—like vegetable oils, animal fats or recycled restaurant grease—are transformed into fuel through a process called transesterification. With the help of a catalyst, an alcohol (typically methanol) breaks the bonds in the fat molecules to create glycerol and long, chain-like molecules called fatty acid esters.

The fatty acid esters, which resemble petroleum diesel’s molecular structure, become biodiesel while the glycerol goes into the wastewater as a byproduct. If left untreated, glycerol can pollute natural water resources by depleting oxygen levels, suffocating fish and other organisms.

Treatment first involved filtering out or breaking down glycerol and other contaminants, but more recent efforts aim to reclaim valuable materials from wastewater, helping offset biodiesel production costs. Biodiesel production is trending upwards, creating an opportunity to tap into the potential of waste streams, the researchers say.

“By developing more stable electrocatalysts, we can begin to harness renewable energy to more efficiently recover value from waste resources,” said Joshua Jack, an assistant professor of civil and environmental engineering at U-M and corresponding author of the study published in Environmental Science & Technology.

One tactic under development called electrochemical CO2 reduction, or eCO2R, uses electricity to convert CO2 from sources like biodiesel exhaust gas into value-added products. However, this process typically relies on high purity water and expensive precious metal catalysts to drive the oxygen evolution reaction (OER) needed for eCO2R.

Researchers have moved towards a cheaper, more energy-efficient alternative to the OER called electrochemical glycerol redox reaction or GOR. The technique instead leverages glycerol’s ultra low redox potential—or strong willingness to exchange electrons—lowering energy demand between 23% and 53% depending on the catalyst.

The catalyst type also determines which chemicals GOR can produce. Nickel has drawn interest recently because of its low cost, ease of manufacturing and ability to produce high-value co-products like formate—a chemical used in food production and storage worth $146 per liter.

“Coupling GOR with a CO2 electrolysis to capture CO2 from the air wraps sustainable wastewater management, CO2 utilization and green chemical synthesis into a single unit process,” said Kyungho Kim, a postdoctoral research fellow of civil and environmental engineering at U-M and lead author of the study.

While recent research has aimed to maximize catalytic activity for GOR, there has been less focus on the stability of catalysts over longer periods of time. To improve the process, the researchers focused on the stability of a nickel catalyst over 24 hours of operation.

The research team first developed a synthetic biodiesel wastewater containing glycerol, methanol, soap and water. Experiments applied an electric potential to the wastewater mimic contained within a flow cell—a device with a nickel positive electrode (anode) and a platinum negative electrode (cathode).

Results detail several previously unknown ways the nickel catalyst lost effectiveness over time. The current declined by 99.7% within 24 hours of operation, mainly driven by particles blocking the nickel electrode.

Implementing a regular cleaning and maintenance schedule will be necessary for long-term usage of the energy-efficient nickel catalysts before adoption in a real-world setting.

“The analytical framework used in this study can offer a new roadmap for evaluating catalyst stability and the experimental results can be used to improve catalyst design and operation in diverse environmental processes,” said Jack.

This study is one of the first steps towards building more robust electrocatalysts that can efficiently operate in wastewater. Full citation: “Delineating catalyst deactivation mechanisms in electrocatalytic glycerol oxidation toward biodiesel wastewater/CO2 co-valorization,” Kyungho Kim and Joshua Jack, Environmental Science & Technology (2025). DOI: 10.1021/acs.est.4c10827

Marketing Communications Specialist

Department of Civil and Environmental Engineering